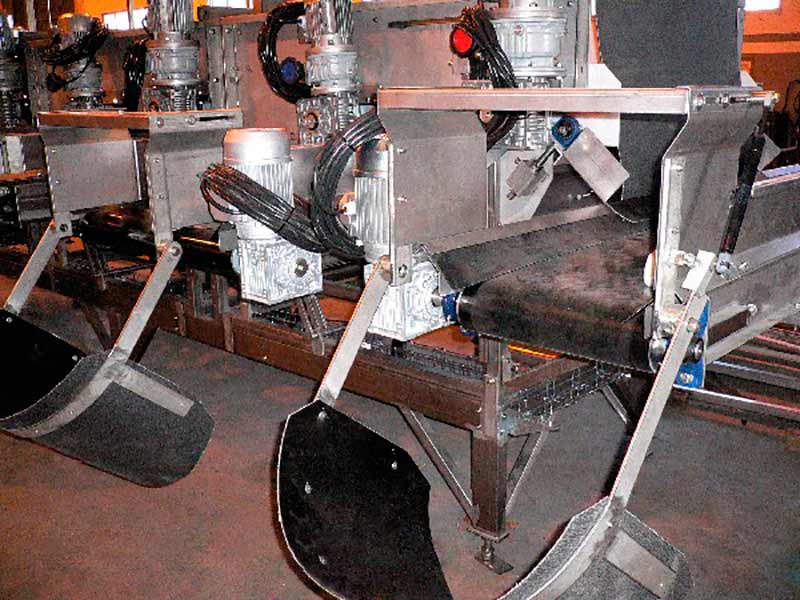

The semi-automatic fall-breaker is a simple and economical system to make the product descend smoothly on the boxes. It is built for any belt width.

In the case where the conveyor belt is very wide, a reduction can be coupled to better fit the semi-automatic fall-breaker.

The semi-automatic fall-breaker can be built fully automatic.

Operation of the semi-automatic fall-breaker

Video and instructions for use

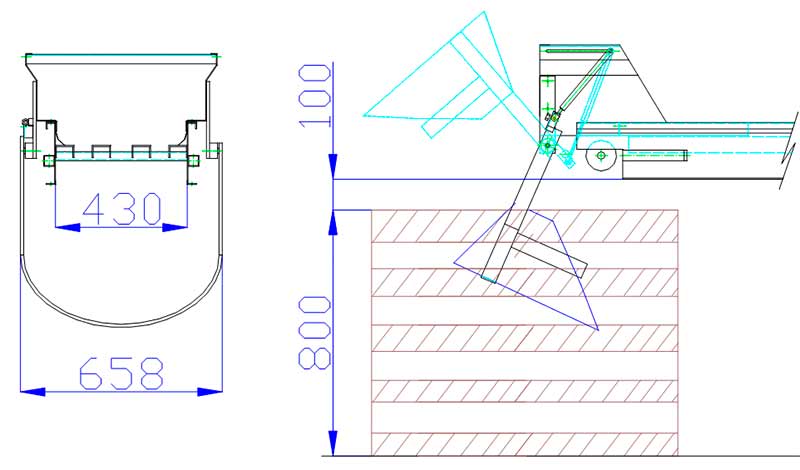

The operator lowers the fall-breaker arc manually, and activates the conveyor travel switch (this switch is optional), and begins to discharge the product on the tarpaulin, slowing down the fall on the box.

When the box is full at a certain height, the weight of the product on the tarpaulin causes the fall-breaker arc to automatically rise to finish filling it.

Once the box is filled, the belt is disconnected from the switch so that the box can be replaced by another empty one.