We have two models of big bag fillers available, the ZIG-ZAG model and the hydraulic, electromechanical model:

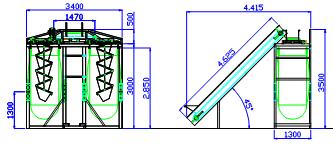

- Model ZIG-ZAG,ideal for productions of 10 Tn/h with a very soft product handle when unloading at close range.

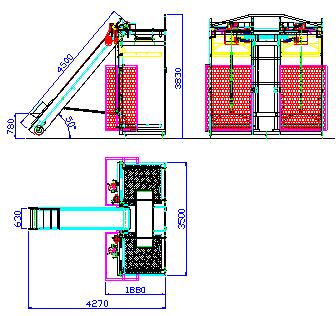

- Hydraulic modelfor productions of 25 Tn/h. Very robust, with a correct treatment of the product. As in all models, the uncoupling of the bag is automatic. On the other hand, the electromechanical model is totally mechanical, very quiet and with very low initial discharge height, which achieves a very gentle treatment of the product.

Bag filler operation

Video and instructions for use

Model ZIG-ZAG Operation

The operator hooks a bag and places a pallet underneath to be able to remove the bag once it is full. After he will command to lower the zig-zag that will stop either when marking the product detector or by an electric limit switch.

The belt and the lift are started in the correct direction to fill the bag. As the bag is filled, the fill detector marks and causes the zig-zag to rise until the signal is lost. This process is repeated until reaching the end of the path and the bag is full. At this point, the belt changes the direction to start filling on the other zig-zag whenever it is prepared, if not, it stops the whole set.

The machine has a filling button that when pressed causes product to be unloaded on either side to adjust the filling of the bag to the customer's taste.

To withdraw the bag, the operator must lift the bag with a pallet and give the order to open the handles to release it. Remove the bag and prepare a new one.

Hydraulic / Electromechanical Model Operation

The operator hooks a bag (the lower pallet is not necessary, but it facilitates a lot of removal of the bag if it is put to the start). It gives the order to raise the platform that will stop when it marks the detector of the product or through an electric limit switch.

The belt and the lift are started in the correct direction to fill the bag. As the bag is filled, the fill detector marks and causes the platform to lower until the signal is lost. This process is repeated until reaching the end of the route and the bag is full. At this point, the belt changes the direction to start the filling on the other platform whenever it is prepared, if not, it stops the whole set.

The machine has a filling button that when pressed causes product to be unloaded on either side to adjust the filling of the bag to the customer's taste.

To withdraw the bag, the operator must lift the bag with a pallet and give the order to open the handles to release it. Then he must remove the bag and prepare a new one.

Photo gallery

- dav